About ChuangJie

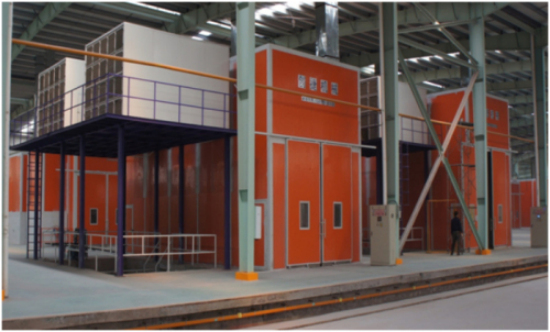

Painting Room for Bus

The spraying system is suitable for surface painting of buses, special vehicles and large construction machinery.

Functions and characteristics of Water-Spinning spraying room:

1. The structure is simple and the construction is fast.

2. The indoor air flow is stable and the paint fog does not disperse.

3. The equipment runs steadily and the purification efficiency is higher than 98%.

4. Because of the principle of fan-induced water supply, there is no conventional pump circulating water supply system, so there is no phenomenon of frequent blockage of equipment.

The function of Water-Spinning spraying room is to confine the mist in the spraying process to a certain area for filtering treatment. The working environment of paint spraying room can meet the requirements of air environment during painting operation, protect the operator's body, control the waste discharged from painting operation, and protect the environment from pollution. It is an important equipment to control the quality of product painting.

Water curtain spraying room provides: (1) clean working environment; (2) full collection of paint mist.

According to the size, shape, weight and production program of the workpiece, water curtain spraying room can be arranged in many ways: open and closed; continuous and intermittent; workpiece rotation or fixing; unilateral spraying and bilateral spraying. In recent years, oil curtain spraying room and sewer curtain spraying room have been developed.

The structure should include: air supply and filtration system, workpiece hanging (conveying and rotating) device, water curtain system, water washing system, air exhaust system, water tank, lighting device and chamber.

Principle of paint mist recovery: Paint mist recovery can be divided into two parts: first, when spraying workpiece, the paint mist and water curtain collide and mix, water curtain will dissolve into part of the paint mist and fall into the water tank; second, the paint mist that does not dissolve into the water curtain through the bottom gap of the water curtain board enters the water washing room, and fully mixes with the water mist sprayed from the atomizing nozzle, and flows after the gas-water separation and settlement. Enter the sink. Lacquer slag is formed by adding paint mist coagulant regularly in the water tank.

Design points:

1. Determine a reasonable configuration.

2. Determine the reasonable average air velocity in the horizontal plane of the spray room.

3. Reasonable matching of air supply and exhaust systems to ensure micro-positive pressure in paint spraying room.

4. The thickness of the water curtain should be uniform, and attention should be paid to the structure of the upper flume and the distribution of the water supply pipeline.

5. The distance from the lower part of the water curtain to the liquid level of the tank should be reasonable.

6. Water-washed atomizing nozzles and pipes should be easily disassembled, replaced and cleaned.

7. Gas-water separation settlement should be sufficient and easy to clean up.