About ChuangJie

ChuangJie Heat reserve burning oven (RTO)

Regenerative incinerator (RTO) is an efficient organic waste gas treatment equipment designed by our company on the basis of digesting and absorbing advanced technology from Europe and America, adopting the mode of "introduction + accumulation + improvement + innovation". The safety, stability and economy of the product have reached the European and American standards and become a good alternative to imported products.

RTO process flow

Technological Principle of Chuangjie Regenerative Incinerator (RTO)

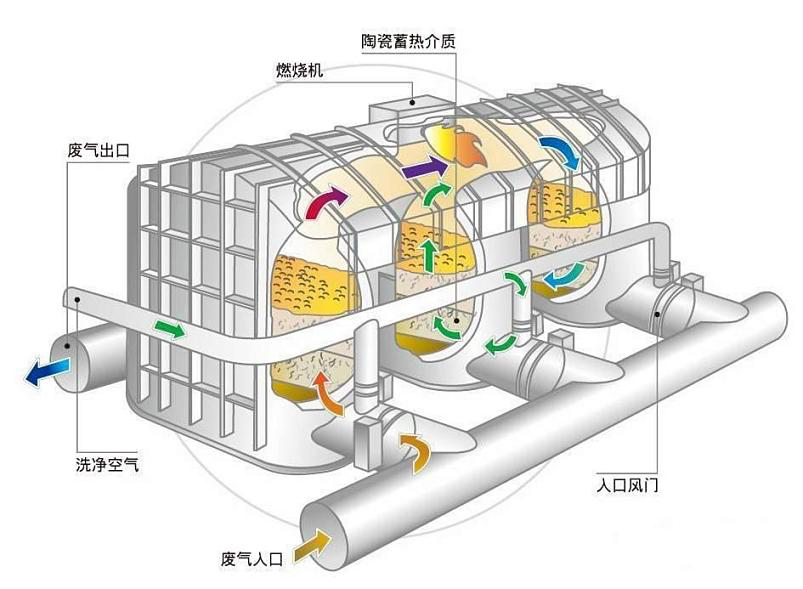

The main structure of the two-bed RTO consists of a high temperature oxidation chamber, two ceramic regenerators and four switching valves. When the organic waste gas enters the regenerator 1, the regenerator 1 releases heat, and the organic waste gas is heated to about 800 C and burned in the high temperature oxidation chamber. The high temperature clean gas after combustion passes through the regenerator 2; the regenerator 2 absorbs heat, and the high temperature gas is cooled by the regenerator 2 and discharged through the switching valve. After a period of time, the valve switch, the organic waste gas enters from the regenerator 2, the regenerator 2 exothermically heats the exhaust gas, the exhaust gas is oxidized and burned through the regenerator 1, the regenerator 1 absorbs heat, and the high temperature gas is cooled and discharged through the switch valve. By periodically switching, the organic waste gas can be continuously treated without or with a small amount of supplementary energy to achieve energy-saving effect.

Three or five regenerative beds can be designed with high VOC emission concentration and emission rate. Each regenerative bed can carry out the cycle of regeneration, exothermic and cleaning in turn.

For organic gases with high concentration (less than 20% LEL), the heat after oxidation can be recovered by secondary waste heat recovery, such as heating heat conducting oil, steam, hot water, hot air, hot air directly reused after filtering, etc.

Principle of RTO Process

Application Scope of Tranquil Regenerative Incinerator (RTO)

Medium and high concentration (less than 20% LEL) and high air volume organic waste gas

There are many kinds of organic components in waste gas, or organic components often change.

Not suitable for waste gas containing more silicone resin

Characteristic of Tranquil Regenerative Incinerator (RTO)

Higher VOC removal rate. Two beds and three beds accounted for more than 95% and 99% respectively.

Ultra-low operating cost. When VOC concentration reaches 450 ppm, no additional fuel consumption is needed, such as higher VOC concentration, and secondary waste heat recovery, which greatly reduces production costs.

Thermal efficiency is as high as 95%.

No secondary pollution such as NOx

Processing air volume ranges from 5,000 to 200,000 cubic meters per hour

Fully automatic control, easy operation and easy maintenance

Parameter Table of Regenerative Incinerator (RTO)